-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration. -

SjakThat's true we enjoy doing business with you.

SjakThat's true we enjoy doing business with you. -

Kelly MarshLiFong is one of our desired vendors in China

Kelly MarshLiFong is one of our desired vendors in China -

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

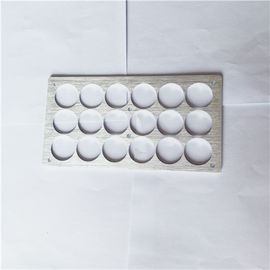

Aluminum Material 5052 Stamping Parts of Lens Holder For Lens Assembly

| Place of Origin | Guangdong, Mainland China |

|---|---|

| Brand Name | LF |

| Certification | ISO9001:2008 |

| Model Number | LF-SQ0911 |

| Minimum Order Quantity | 2000 PCS |

| Price | Negotiable |

| Packaging Details | Ply wood Frame Or Customized |

| Delivery Time | MOQ 10 Days, 50,000pcs 4 Weeks. |

| Payment Terms | TT, L/C |

| Supply Ability | 150,000 PCS Per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Overall Dimension | L216*215*H1.53mm | Board Wall Thickness | 1.53mm |

|---|---|---|---|

| Material | Aluminum 5052 | Part Net Weight | 20 Grams |

| Inner Circle Diameter | 22mm | Application | For Lens Assembly |

| Highlight | precision metal stamping,custom made metal stamps |

||

Aluminum Material 5052 Stamping Parts of Lens Holder For Lens Assembly

Description:

Large Image: Aluminum Lens Holder

Application:

For Lens Assembly

Specification:

| Overall Dimension | L216*215*H1.53mm |

| Board Wall Thickness | 1.53mm |

| Inner Circle Diameter | 22mm |

| Part Net Weight | 20 Grams |

| Material | Aluminum 5052 |

Processing Technic:

1. Computer Stamping to Forming

2. Finish: Double Side Brush Finish

3. Acid Wash, then Clear Anodize

4. Quality Check

5. Packing

Facility:

Automatic Stamping Machine

![]()

Brush Finish Room

Advantages:

1. Professional Research and Design Team, Necessary Equipments: Automatic Cutting Machine, Laser Cutting Machine, Automatic Press, Cold Press, Bending Machine

2. Strict Quality Control in Each Process and Finish Product Quality Control

3. Short Delivery Lead Time: 15-30 Days

4. Optional For OEM or ODM

5. Comprehensive After-Sale Service, Quick Responses For Daily Communication