-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration. -

SjakThat's true we enjoy doing business with you.

SjakThat's true we enjoy doing business with you. -

Kelly MarshLiFong is one of our desired vendors in China

Kelly MarshLiFong is one of our desired vendors in China -

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

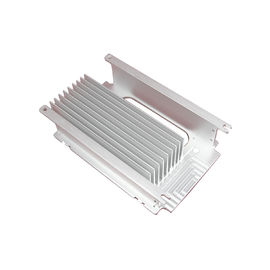

Solar Energy Equipment Extruded Aluminum Heatsink , Silver Anodize Treatment

| Place of Origin | Guangdong, Mainland China |

|---|---|

| Brand Name | LF |

| Certification | ISO9001:2008 |

| Model Number | LF-ET0423 |

| Minimum Order Quantity | 100 PCS |

| Price | Negotiable |

| Packaging Details | Part in Bubble Bag, then in Cartons, Wooden Pallet on Bottom, Film wrapped overall then Nylon belt fastened Or to be Customized Means of Packing. |

| Delivery Time | MOQ 1 Week, 10,000pcs 4 Weeks. |

| Payment Terms | TT, L/C |

| Supply Ability | 15,000pcs Per Month |

| Highlight | aluminum heatsink extrusion,aluminum extruded heatsink |

||

|---|---|---|---|

Solar Energy Equipment Extruded Aluminum Heatsink , Silver Anodize Treatment

Application:

For Solar Energy Equipment

Specification:

| Overall Dimension | L250*W160*H60mm |

| Surface Treatment | Silver Anodize (Anodized Film Thickness > 12 microns |

| Part Weight | 2.5kgs |

Material:

Al6063 T6

Type of Aluminum Alloy 6063 brings very good Heat dissipation; Excellent Performance In Corrosion

Resistant after anodize as well.

Processing Technic:

1.Extrusion Tooling Making--Prototype/T1--Dimension Check-- Sample Approval-- SOP

2.Extrusion-- Cutting Short-- CNC machining--Dilling Holes/ Threading-- Quality

Check (dimension and surface) -- Acid Washing-- Black Anodize -- FQC (Surface Vision

Checking)-- Packing

3. Brush Finish Brings Very High End Surface Looking and Good Feeling For Touching.

Advantages:

Professional Research and Design Team, Processes All Necessary Equipments: Extrusion Machine:

2 Sets; CNC Machine: 10 Sets (Maximum working platform: 1200*80),

Drill/threading machining: 25 Machines

1.Strict Quality Control in Each Process and Finish Product Quality Control

2.Short Delivery Lead Time: 15-30 Days

3.Optional For OEM or ODM

4.Comprehensive After-Sale Service, Quick Responses For Daily Communication