-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration. -

SjakThat's true we enjoy doing business with you.

SjakThat's true we enjoy doing business with you. -

Kelly MarshLiFong is one of our desired vendors in China

Kelly MarshLiFong is one of our desired vendors in China -

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

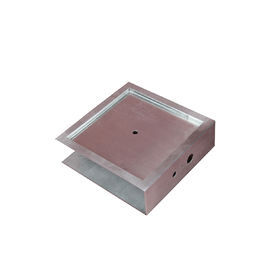

1.0mm 400Grams Metal Stamping Parts , Bar Stamping Square Wine Seat

| Place of Origin | GuangDong, Mainland China |

|---|---|

| Brand Name | LF |

| Certification | ISO9001:2008, TS16949 |

| Model Number | LF-SQ0908 |

| Minimum Order Quantity | 1000 PCS |

| Price | Negotiation |

| Packaging Details | Ply wood Frame Or Customized |

| Delivery Time | MOQ 10 Days, 3000pcs 4 Weeks |

| Payment Terms | TT, L/C, Western Union |

| Supply Ability | 1000000tons/month |

| Highlight | precision metal stamping,custom made metal stamps |

||

|---|---|---|---|

1.0mm 400Grams Metal Stamping Parts , Bar Stamping Square Wine Seat

Description:

(1)Square Wine Seat

| Overall Dimension | L120*W102*H40mm |

| Board Wall Thickness | 1.0mm |

| Seat Net Weight | 400 Grams |

Advantages:

1. Professional Research and Design Team, Necessary Equipments: Automatic Cutting Machine, Laser Cutting Machine, Automatic Press, Cold Press, Bending Machine

2. Strict Quality Control in Each Process and Finish Product Quality Control

3. Short Delivery Lead Time: 15-30 Days

4. Optional For OEM or ODM