-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration. -

SjakThat's true we enjoy doing business with you.

SjakThat's true we enjoy doing business with you. -

Kelly MarshLiFong is one of our desired vendors in China

Kelly MarshLiFong is one of our desired vendors in China -

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

Raimund SchenkProduct Quality, Competitve Prices, always one of our key suppliers

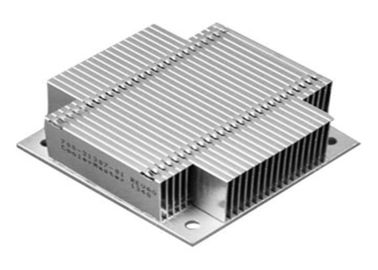

Die Stamping Copper Fin CPU Copper Pipe Heat Sink Aluminum Bottom Heatsink

| Material | Pure Copper C1100 Strips | Process | Die Castings |

|---|---|---|---|

| Aplication | CPU | Color | Design |

| Type | Heatsinks | ODM&OEM | Yes |

| Highlight | copper heat sink,extrusion heat sink |

||

Die Stamping Copper Fin CPU Aluminum Bottom Heatsink Copper Pipe Heat Sink

Specifications:

1. Overall dimensions: L56*W56*H26mm

2. Copper fin thickness: 0.4mm

3. Fin quantity per row: 28pcs * 16pcs

4. Aluminum bottom wall thickness: 2mm

5. Part weight: 56 grams

6. Materials: pure copper C1100 strips, purity over 99.5% (Standard: JISH3250-2006), pure aluminum board A1060 purity over 99.6% (Standard: GB/T3880-2006)

Little impurity brings very good electrical and heat conduction, excellent performance in corrosion resistant as well

Processing technic:

1. Copper fins: progressive die stamping

2. Aluminum enclosure and board: forming die stamping

3. Aluminum board and enclosure nickel plated, copper fin passivate (insulation, oxidation and corrosion resistance)

4. Assembly: automatic fin wearing/assembly, then fixed by overflow soldering and screw/rivet combination

5. Quality check

6. Packing

Description:

|

Copper Pipe Heat Sink | |

| Item No. | LF-Y8202 | |

| Service | Drawings or sample processing | |

| Materials | Pure Copper C1100 Strips,JISH3250-2006,GB/T3880-2006 | |

| Precision processing | progressive die stamping,forming die stamping,automatic fin wearing/assembly,fixed by overflow soldering,screw/rivet combination | |

| QC (inspection everywhere ) | 15-30days,it is up to the order. | |

| Package | PP bag/carton or according customers' requirement | |

| payment term | T/T,L/C |

Advantages:

1. Professional research and design team, strong &automatic equipment

2. Progressive stamping, automatic soldering machine

3. Strict quality control in each process and finish product quality control

4. Short delivery lead time: 15-30 days

5. Optional for OEM or ODM

6. Comprehensive after-sale service, quick responses for daily communication

Factory

![]()